Overview

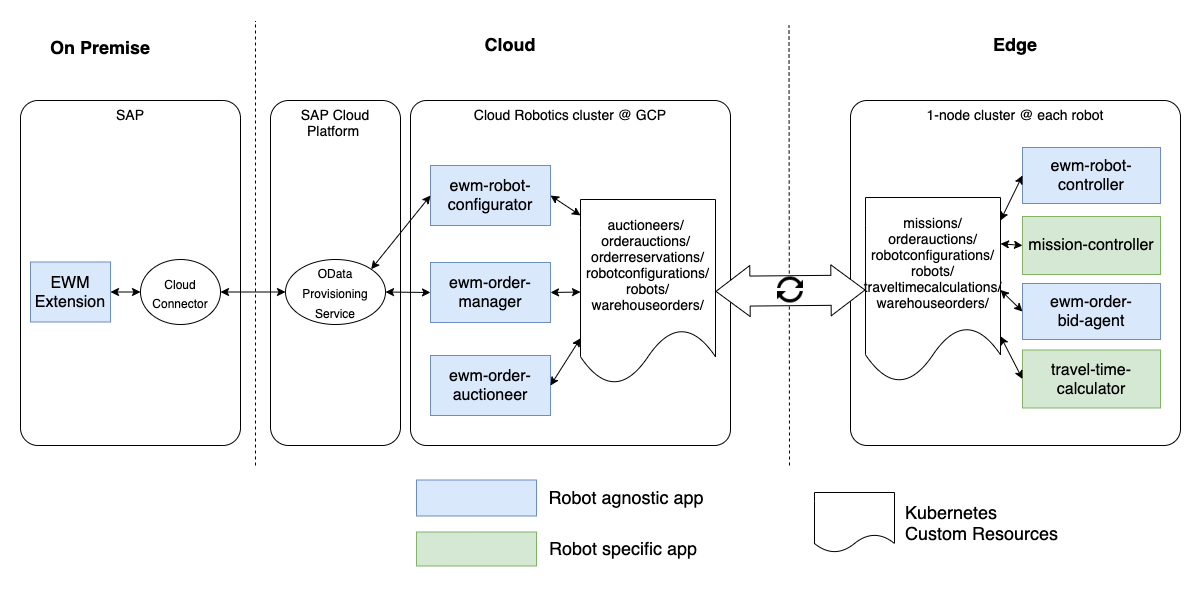

SAP EWM Cloud Robotics is built on top of Google’s open source Cloud Robotics infrastructure.

Our apps are using their Federation Layer based Kubernetes Custom Resources for app to app communication including the distribution of SAP business objects to the robots.

Application management for all apps is done centrally from the Cloud using the App Management Layer of Cloud Robotics.

For interaction with SAP EWM Cloud Robotics is using OData interfaces. The OData Provisioning Service in SAP Cloud Platform layer is optional to create an OData endpoint in the Internet. There are alternatives like exposing the SAP Gateway of the backend system itself to the Internet.

The architecture you see here is the target architecture for autonomous warehouse robots which are able to process their queue warehouse orders even when they lose connection to the network while doing so. This is possible because the ewm-robot-controller which includes the business logic of how to process warehouse orders is running on the robot itself.

All applications meant to run on the edge Kubernetes cluster could easily be deployed in the cloud Kubernetes cluster too. But those robots are not completely independent from network outages anymore. It is possible to combine both options in one single installation. This could be useful in case you have different types of robots where some are supporting only one scenario and some the other.

In detail

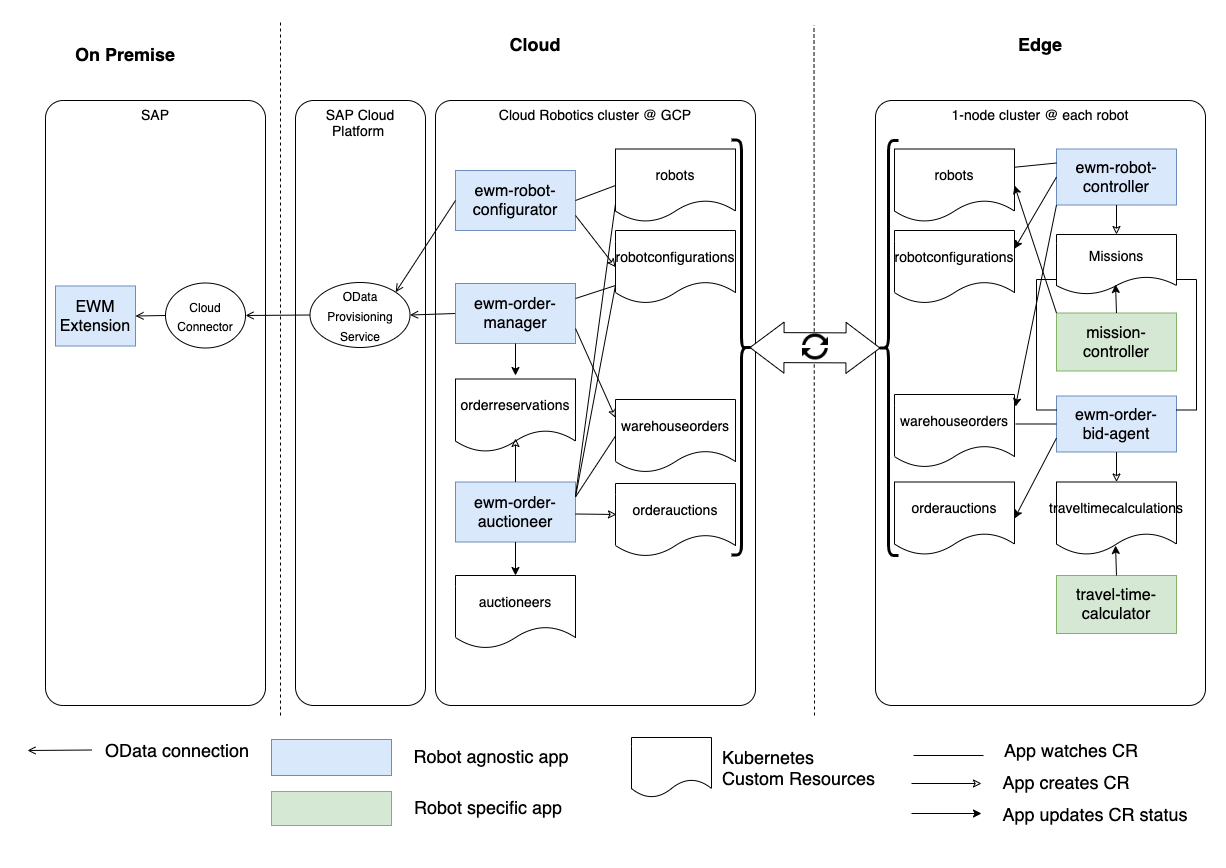

The EWM Cloud Robotics apps in general are stateless. Their state is stored either in Custom Resources or in the SAP EWM Backend. The ewm-robot-controller app is an exception to that rule. It includes a state machine which inherits the business logic of how robots process warehouse orders. But even the state of this app can be restored at any time from Custom Resources.

These Custom Resources are used as interface between the apps and can be synchronized by the Federation Layer mentioned before. For a better understanding of this architecture it is important to keep in mind that a Custom Resources consist of spec and status (plus additional attributes like metadata etc.) as many other objects in the Kubernetes world too. Whenever you create a new Custom Resource, you define its spec. The Federation Layer is able to synchronize the spec from the Cloud to one or multiple robots and the status from robots to Cloud or the other way around. This is defined in the Custom Resource Definitions. Cloud and robots never write both to spec and status of the same Custom Resource Definition.

The definition of all our Custom Resources are available as helm charts in our repository.

Warehouse order processing

The execution part of our solution describes the way how robots process warehouse orders. You find details about the process flow here Therefor, we use primarily ewm-order-manager and ewm-robot-controller apps on the process side and mission-controller apps to send commands to robots. robot-configurator app ensures that our robots are created and up-to-date in SAP EWM backend.

The most important custom resource in this context is the Warehouse Order. Its spec is created by ewm-order-manager and synchronized with the robot which processes it. On the robot side ewm-robot-controller processes the warehouse order and updates its status with the progress (warehouse task confirmations). Status is synchronized too whenever there is network connectivity, that ewm-order-manager is able to send the confirmations to SAP EWM using our OData interface.

While processing the warehouse order ewm-robot-controller creates multiple Mission custom resources in order to move the robot to the right places. A mission-controller is responsible to process these missions and update their status accordingly. Mission-controllers are implemented robot specific. This means the Mission is our open interface specification to control warehouse robots.

The Robot Configuration custom resource contains the current configuration of each robot as well as its status. The configuration is maintained in the Cloud cluster using our EWM monitoring UI and synchronized to the robots, the ewm-robot-controllers update the status.

The whole process can run processing warehouse order in the sequence defined in SAP EWM backend without further optimization. In this case ewm-order-mananger is constantly checking the state of the robots. When the warehouse order queue of a robot is empty and its state (battery level etc.) allows processing of new orders, it assigns the first warehouse order from SAP EWM. This basic behavior can be enhanced with an optimization which follows the approach of an auction you find in the next chapter.

Warehouse order auctions

Warehouse order auctions are a simple optimizing approach which works without knowledge about the specification (speed, acceleration, etc.) of the robots we are using. The only prerequisite is that participating robots are able estimate how long it takes getting from point A to point B. For further details about this process please check this document.

This part of the process requires ewm-order-manager, ewm-order-auctioneer and ewm-order-bid-agent apps on the process site and a travel-time-calculator app for communication with the robot.

The process is controlled by ewm-order-auctioneer which is configured in the Auctioneer custom resource. The app watches several custom resource like warehouse orders, robot configurations, robots, order auctions and order reservations to identify when a new auction should be started and which robots should be able to bid. Whenever this is the case it starts requesting warehouse orders for the auction from ewm-order-manager by creating an Order Reservation custom resource. When found ewm-order-manager reserves them in SAP EWM backend and adds them to the Order Reservation status. Those warehouse ordered are attached to one Order Auction custom resource per robot by ewm-order-auctioneer and distributed to the robots.

On the robots ewm-order-bid-agent create bids for each warehouse order of the auction it is able to process and returns them in the status of the Order Auction. Therefor, it identifies the paths the robot needs to drive based on the current workload identified from warehouse order and mission custom resources and requests the run time for each path by creating a Runtime Estimation custom resource. Runtime Estimations are our open interface for this process. They are processed by a robot specific travel-time-calculator app.

Back in the cloud ewm-order-auctioneer collects the bids from status of all Order Auction custom resources and determines the winner robots of the auction. The winners are attached to the spec of the corresponding Order Reservation custom resource, that ewm-order-manager is able to assign them to the warehouse orders in SAP EWM backend. Warehouse order processing process can now continue with an optimized sequence of warehouse orders.

Integrating new robot models

It is relatively easy to integrate new robot models into our architecture. The only apps which have to be implemented robot specific are mission-controller and travel-time-calculator apps mentioned in the previous chapters.

A mission-controller implements processing of Mission custom resources and status update of the Robot custom resource you can find here. For getting started please have a look at our implementation of mir-mission-controller in python.

The travel-time-calculator implements processing of Runtime Estimation custom resources. There is an existing implementation too. Check the mir-travel-time-calculator written in Go. Additionally you finds a Go implementation of many data types we use in our Go packages.

Have fun

🤖